Serac Asia Sdn Bhd revolutionises bottle cap sterilisation with BluStream at Malaysia Technology Excellence Awards 2024

It offers beverage manufacturers a solution for continuous packaging sterilisation.

Serac Asia Sdn Bhd has set a new benchmark in the manufacturing sector by winning in the Manufacturing Technology - Manufacturing category at the Malaysia Technology Excellence Awards 2024. The company has been recognised for its innovative BluStream cap decontamination module, a groundbreaking solution in ESL (Extended Shelf Life) and aseptic packaging. This technological advancement heralds a new era of bottle cap sterilisation, offering unprecedented levels of efficiency, safety, and environmental friendliness.

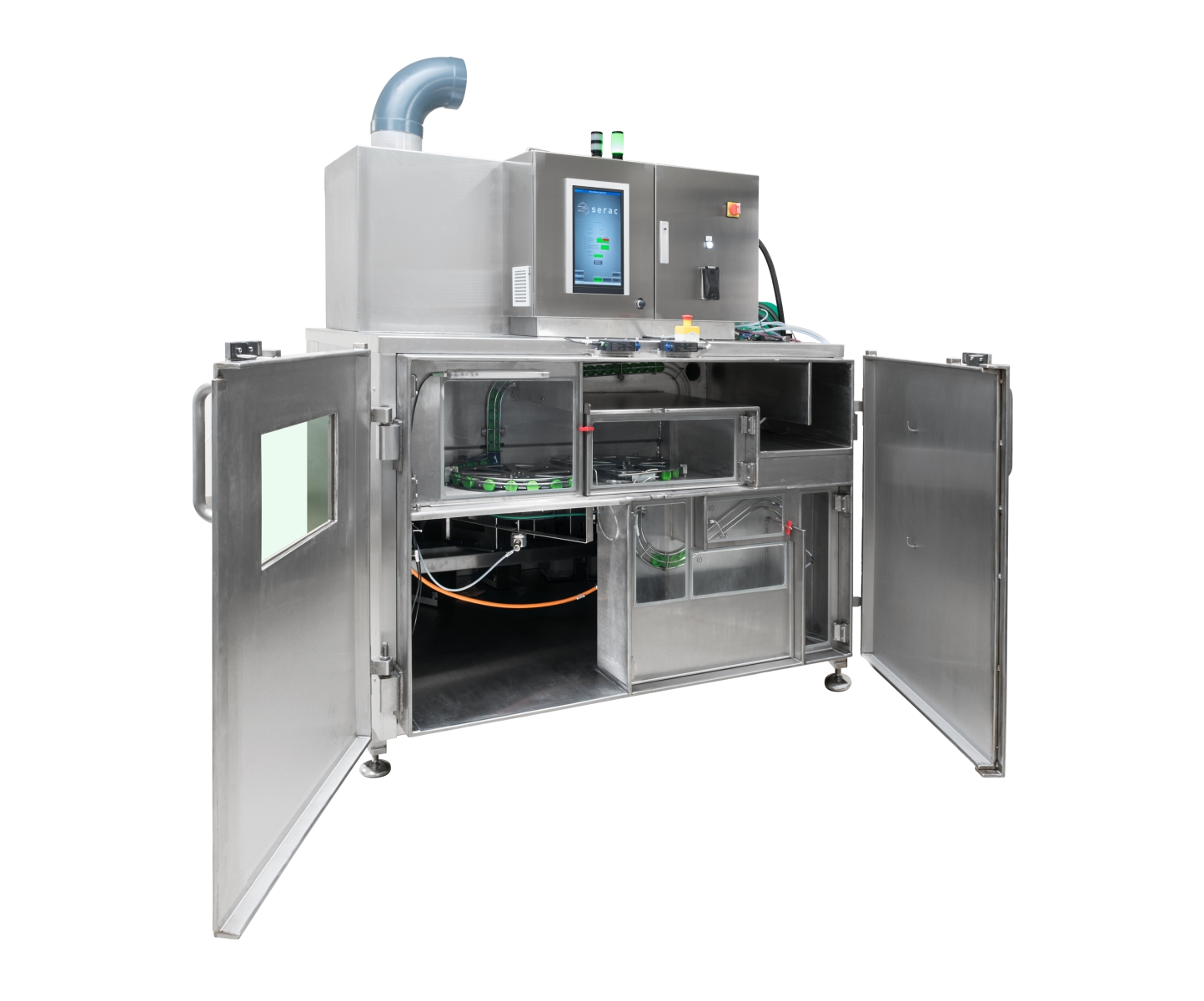

The Serac BluStream module occupies merely 3sqm of floorspace, showcasing its compact design. Remarkably versatile, it can be seamlessly integrated into new Serac lines or retrofitted onto existing machines, regardless of their original equipment manufacturer (OEM). Designed to cater to both high-acid and low-acid beverages, the BluStream module boasts a capability of treating 900 at 600 caps per minute (cpm), some tests have been done up to 900 cpm.

At the core of Serac's innovation is the utilisation of low-energy e-beam technology for cap decontamination. This process involves bombarding the cap surface with electrons, effectively dismantling microorganisms by breaking their DNA chains. Notably, this physical, dry treatment is conducted at room temperature, ensuring the cap's internal structure remains unaffected. Consequently, there is no risk of cap distortion that could impair functionality.

BluStream's efficiency is nothing short of remarkable, achieving a 6-Log bacteriological reduction within the cap in just 0.3 to 0.5 seconds. This level of efficacy is crucial for aseptic packaging and maintaining high output standards. Furthermore, the absence of chemicals like PAA and H2O2 in the BluStream process underscores its safety advantage for consumers. Sterilisation monitoring is simplified to three critical parameters: voltage, current intensity, and exposure time. This real-time monitoring capability, coupled with in-line dosimetry tests, virtually eliminates the risk of chemical residues, inadequate treatment, or undetected faulty caps.

Operator safety is another highlight of the BluStream module. Compared to traditional sterilisation units, BluStream operates quietly and without the release of unpleasant chemical odours. The low amount of ozone generated during the process is safely extracted outside the factory premises, ensuring a comfortable operating environment. This feature not only benefits the operators but also contributes to ozone's natural depletion in the environment without leaving any trace.

From an environmental standpoint, the BluStream module is a game-changer. Its chemical-free nature means no toxic effluents are generated. Additionally, its operation does not require water, heating, or steam, significantly reducing energy and water consumption compared to conventional sterilisation methods.

Serac's BluStream module offers beverage manufacturers a sterling solution for continuous cap sterilisation at high outputs, without compromising on consumer safety, operator well-being, or environmental sustainability. It is compatible with any type of cap material, including HDPE, LDPE, PET, PP, across all bottle sizes, making it a versatile choice for the industry. This award-winning innovation not only positions Serac Asia Sdn Bhd at the forefront of manufacturing technology but also represents a significant leap towards safer, more efficient, and environmentally responsible production processes.

The Malaysia Technology Excellence Awards recognises exceptional companies at the forefront of technological innovation and digital transformation in Malaysia’s rapidly growing economy.

The Malaysia Technology Excellence Awards is presented by Asian Business Review Magazine. To view the full list of winners, click here. If you want to join the 2025 awards programme and be acclaimed for your company's outstanding contributions in pursuit of technological innovation, please contact Danica Avila at [email protected].

Advertise

Advertise